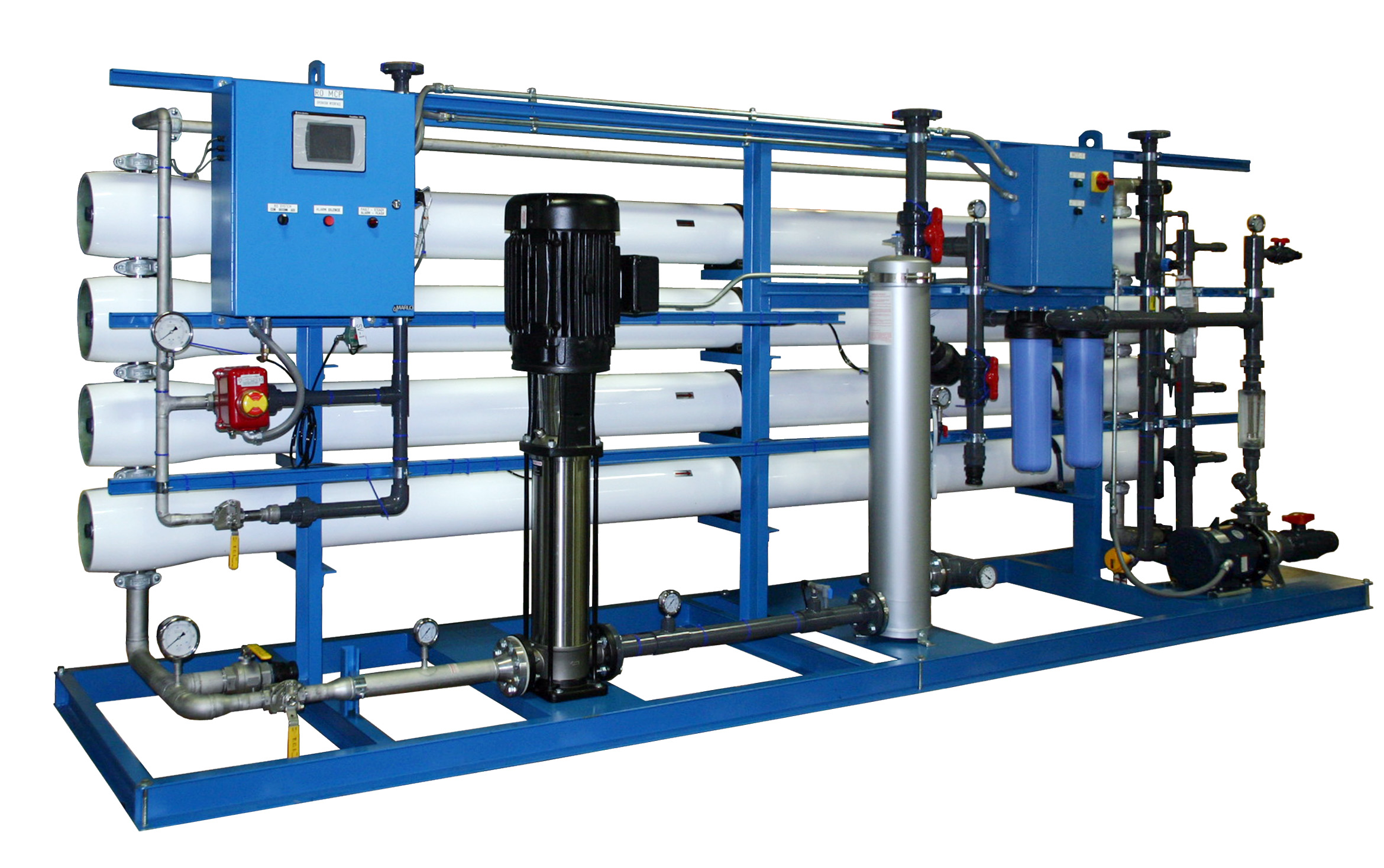

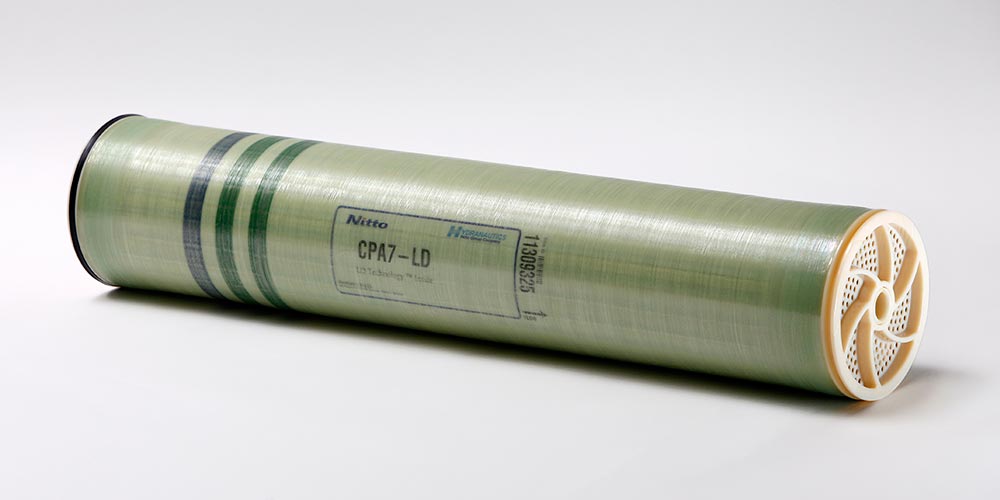

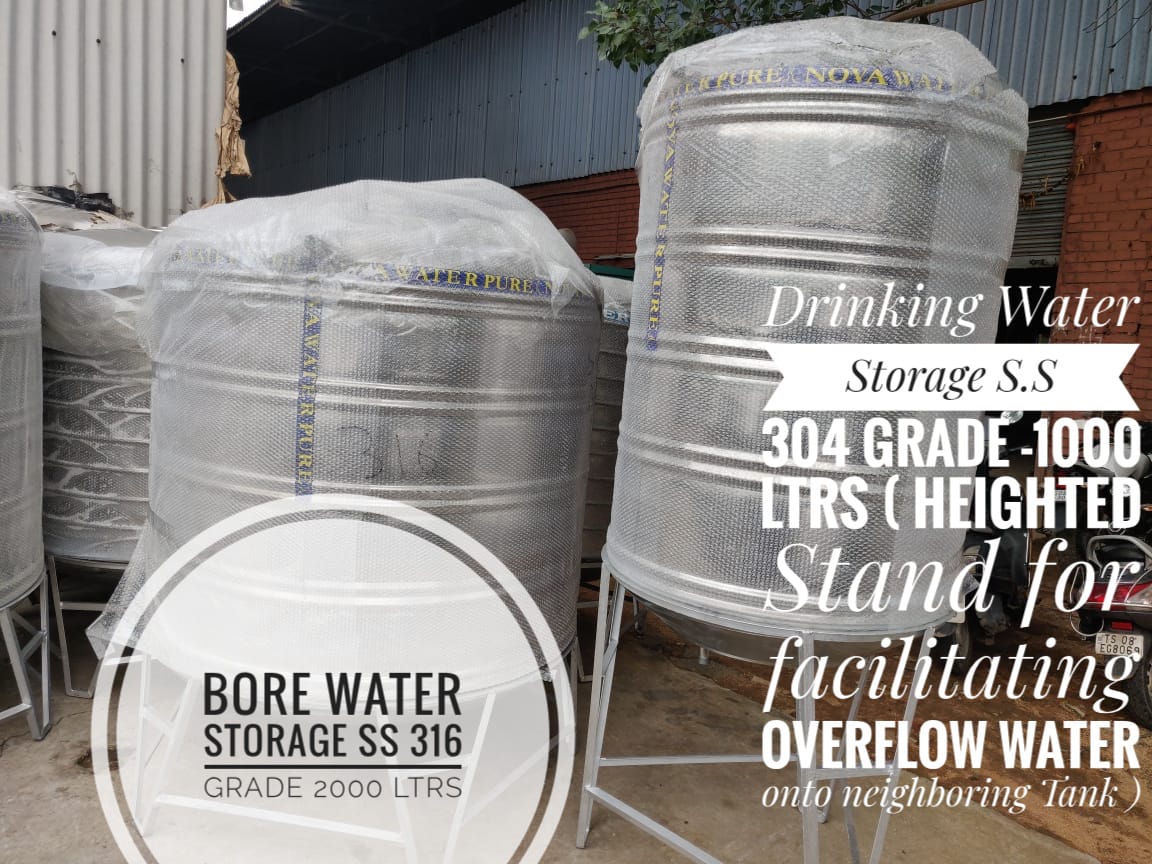

RO Water Plant (100 LPH to 20,000 LPH) – Advanced Reverse Osmosis Water Purification Systems Our RO Water Plants are engineered to deliver high-quality purified water for a wide range of applications — from small-scale domestic needs to large industrial requirements. With capacities starting from 100 liters per hour (LPH) up to 20,000 LPH, these systems provide reliable, efficient, and cost-effective water purification solutions tailored to your volume needs. Key Features: Wide Capacity Range: Choose from compact 100 LPH units ideal for small offices or communities, to heavy-duty 20,000 LPH plants designed for industries and commercial complexes. Advanced Filtration Technology: Utilizes multi-stage filtration including pre-filters, precision RO membranes, and post-treatment options ensuring removal of dissolved salts, harmful chemicals, bacteria, viruses, and suspended solids. Energy Efficient & Cost-Effective: Designed with energy-saving pumps and optimized membrane performance for lower operational costs. Durable & Corrosion-Resistant Construction: Built with high-quality stainless steel and robust components to ensure long service life and minimal maintenance. User-Friendly Control Panel: Equipped with automated control systems including flow meters, pressure gauges, and alarms for seamless operation and monitoring. Customizable Configurations: Available with additional features such as UV sterilization, chemical dosing, and storage tanks tailored to specific water quality and usage needs. Applications: Drinking water supply for residential complexes, offices, schools, and hospitals. Process water for industries including pharmaceuticals, food & beverage, and electronics. Commercial uses such as hotels, restaurants, and water bottling plants. Agricultural and irrigation needs where purified water is required. Why Choose Our RO Water Plants? High Purity Water: Ensures safe, clean, and great-tasting water. Scalable Solutions: Perfectly sized units for any volume requirement. After-Sales Support: Expert installation and maintenance services. Compliance: Meets national and international standards for water purification.

Send Message