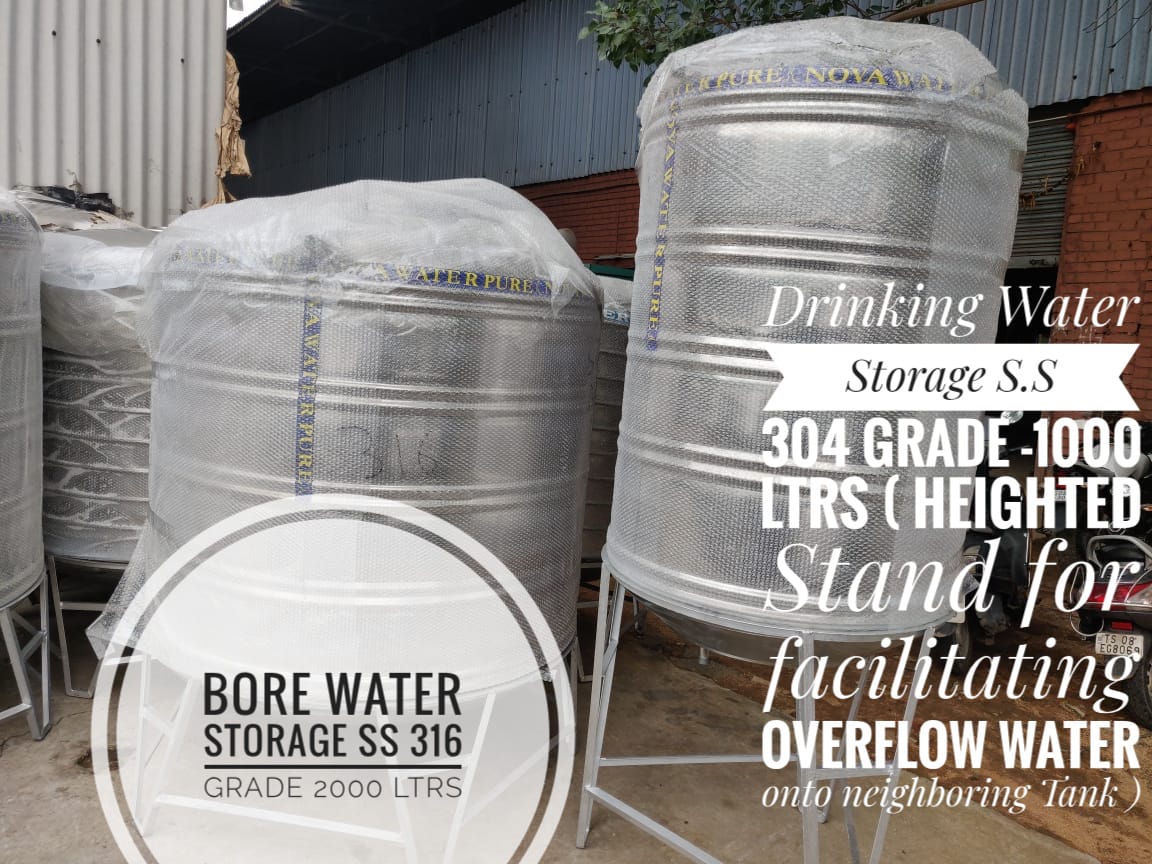

Stainless Steel (SS) Storage Tanks for RO Water Storage – Durable & Hygienic Solutions Our Stainless Steel Storage Tanks are specially designed to store RO purified water safely and hygienically. Available in thickness ranges from 0.5mm to 1mm and manufactured using high-grade SS 304 and SS 316 stainless steel, these tanks provide a robust and corrosion-resistant solution for all your water storage needs. Product Details: Material Grades: SS 304 (standard corrosion resistance) and SS 316 (enhanced corrosion resistance, ideal for aggressive environments) Thickness Range: 0.5mm to 1mm, customizable based on capacity and application requirements Capacities: Custom-built to suit overhead tanks, underground storage, or process water storage for RO plants Finish: Smooth, hygienic, and easy-to-clean inner surface ensuring water purity Typical Uses: Overhead Water Storage Tanks for residential and commercial buildings RO Water Storage Tanks for purified water holding before distribution or usage Process Water Storage in pharmaceutical, food & beverage, and other industries requiring clean water Safe Storage of potable and drinking water to maintain quality over long durations Benefits of SS Storage Tanks: Corrosion Resistant: Stainless steel construction prevents rust, scaling, and contamination, ensuring long-lasting performance. Hygienic & Non-Toxic: SS 304 and SS 316 materials meet stringent health standards, preventing bacterial growth and water contamination. Durable & Strong: With thickness from 0.5mm to 1mm, the tanks withstand physical impacts and environmental stresses. Low Maintenance: Easy to clean with minimal upkeep required, reducing downtime and maintenance costs. Temperature Resistant: Suitable for a wide range of temperatures without deformation or loss of integrity. Eco-Friendly & Recyclable: Stainless steel is fully recyclable and environmentally safe. Aesthetic Appeal: Polished finish adds a sleek, modern look suitable for visible installations.

Send Message